Keeping an eye on coolant temperature is very important. Regular cleaning of your radiator is a vital part of caring for your machine. In severe dusty conditions, this may need to be carried out each day. Usually blowing out the radiator core with compressed air or even a garden leaf blower – in the opposite direction of machine air flow – will make a huge difference.

The problem with air that is pushed through the radiator core during machine operation, is that there are contaminants that come with the air – grass, grass seed, feathers, leaves, paper, plastic, etc. If you have an oil or fuel leak, the problem can be even worse.

The way most machines are configured today, there are multiple cores stacked in front of each other – coolant; hydraulic/transmission oil; air con. Unfortunately, even regular cleaning efforts will not keep these cores clear. Grass & leaves tend to get caught up in between these cores & the only way to clear them is by complete removal.

Small excavators are very susceptible to this problem. I have also seen this occur on backhoes, dozers, skidsteer loaders, to name a few. Recently a customer with a Case CX50B was complaining about his overheating problem & couldn’t understand why, as he was very conscious of blowing out the radiator on his machine. As soon as I walked past the rear of his machine at full RPM, I could tell it was not pushing out enough air. I convinced him to remove the radiator & separate the oil cooler from the radiator core to see if there was any restriction.

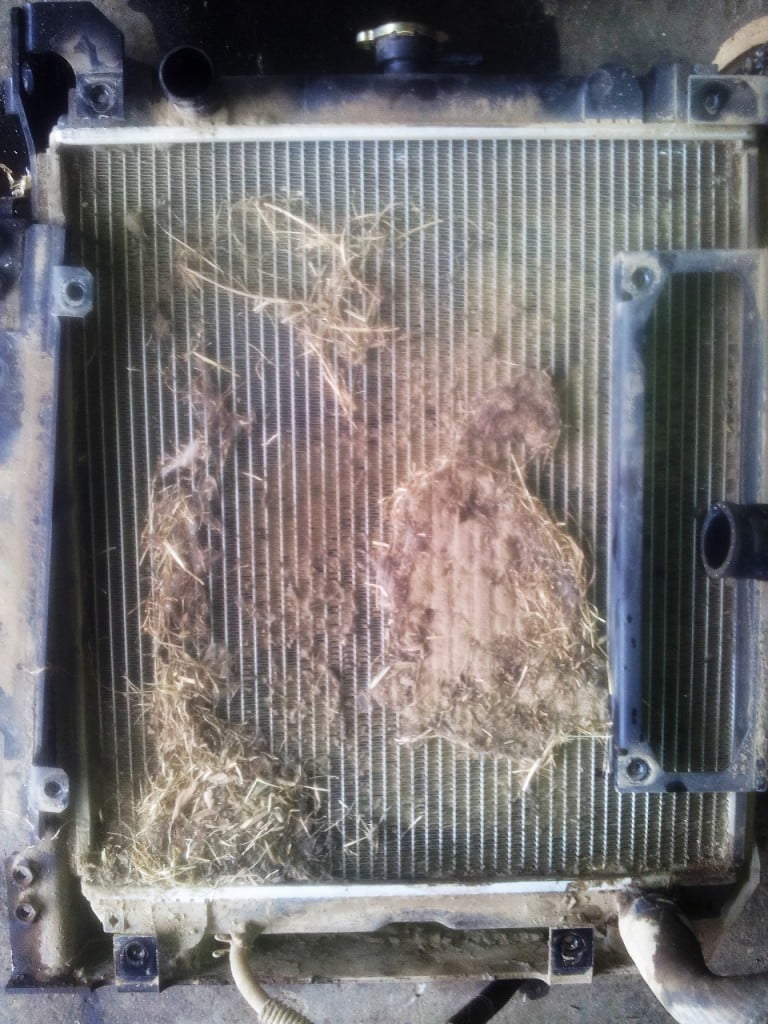

As you can see, there is quite a bit of restriction occurring here. This was just enough to push the temperature gauge into the red after about an hour of digging.

After a clean out & refitting the radiator & cooler assembly, we checked the air flow at full RPM again, well, he was lost for words, he just kept shaking his head in disbelief, – another happy ALR customer :-).

In summary, these problems don’t happen overnight. It slowly changes the conditions of the machine, sometimes over 2-3000 hrs – even if you think “it should be OK, I clean that out all the time!” – Be assured, if you have multiple cooling cores on your machine they will eventually look like this!

I have a jcb skidsteer and the hydralic oil seems to be overheating .is there adjustments i can make

Hi Rob,

‘Seems to be’ overheating, are you going off an actual temperature reading of the oil?

Does it get hot enough to hear the oil boiling?

Is an alarm going off?

If it is overheating, how long does it take to reach temperature?

Will it cool down if you stop operating the machine & run at high idle?

Will the engine continue to run at idle speed?

There are no ‘adjustments’ to repair overheating, but a little more information may help a diagnosis.

Cheers

I work with an engineering firm and we have 3sets of backhoe loaders which we engaged in our field operations. But of recent, it was observed that all the 3 backhoe loaders are experiencing overheating even though we have tried separating the radiator and the coolant to clean out the dust because we actually work in a dusty environment and other possible checks but yet it’s still overheating.

What can be the possible cause?

Hello Herbert,

Depending if the ambient temperature is high, I would think for three machines to have the same problem at the same time, would mean there is an issue with the design of the cooling system.

Possibly the radiators are too small or there is insufficient air flow passing through them?

Regards

alrman

I have a John Deere 210C tractor backhoe and the alarm for over heating keeps going off. Have changed thermostat and new coolant. That didn’t work. Did notice that the upper radiator hose was hot while the lower hose was luke warm. Does that indicate a bad waterpump?

Hi Mike,

I’m not really a JD specialist…..

However, If you can touch the radiator hoses with the alarm sounding, I wouldn’t think the engine is actually overheating.

I would be testing the engine temperature with a heat gun, just to verify it’s actually ‘hot’ or not.

Likely, you have a faulty temperature sensor OR a problem with the wiring between the sensor & the dashboard.

Hope this helps

alrman

Hi

I have a Case 450 track loader/Drott

The oil cooler is leaking in to the radiator

It is built into the bottom of the radiator.

The radiator seems to be ok

I can bypass the oil cooler just wondering if I Can install an external oil cooler in front of the radiator.

I have had no luck in finding a replacement radiator for it unless I buy new from America.

Any help would be greatly appreciate.

Thanks Mitch

Hey Mitch,

Fitting an external oil cooler is likely your best option.

I have done this a couple of times the past with bigger machines, but never a 450.

A proper “old school” heavy equipment radiator repairer should be able to repair your original radiator – but these guys are disappearing, the company I used for a long time closed down a couple years ago & I have not yet found one to do the same type of work as they did.

Trying to find a suitable external oil cooler – with size & fittings is the problem.

You will need to vist/call some wrecking yards & see what they have.

The times I have done this before, I used oil coolers from wrecked farm tractors.

No doubt, you may need to alter the cross bracket/brace in front of the radiator.

Hope you can get what you need.

alrman