Recently we had a call from a new client who was having trouble with their brakes on a Case 580SK Backhoe. They had owned the machine for over ten years & said that they felt the brakes had never really performed as they should. The machine was “only used once or twice a week, for a few hours at a time, maybe”, a company that maintains the methane gas reclamation at an old landfill site. So they persevered with the machine the way that it was – brakes not pulling the machine up strongly, with brake shudder & chatter, thought to be just old oil issues – for years!

But not too important to worry about……

Eventually the LH side pedal would not work or would the master cylinders hold oil – so finally, they thought it was time to get something done about it.

Below is what was found as we tipped the transmission oil filter into a drain tin …. 😮

This is never what someone wishes to see coming from an upturned oil filter!

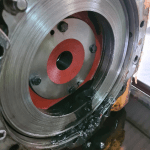

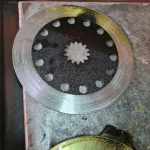

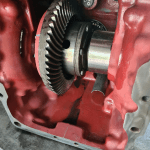

The transaxle was removed on-site & transported back to the ALR laboratory for a full autopsy. The axles were removed to expose the brakes & as suspected, the LH brake was severely worn. Almost 8mm was worn from the LH brake piston – all the brake lining on the brake disc was gone & the two were grinding into each other, sending a large amount of iron filings through the transaxle.

The RHS was also very worn, but caught just before metal to metal contact was made between disc & piston.

Surprisingly, the actual brake piston bore in the main transaxle housing was not damaged beyond needing no more than a little rub with some emery cloth.

Take a look at the amount of iron filing material inside the rear section of the transaxle! –

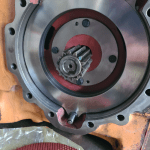

The entire transaxle was cleaned of all contaminants & new brake discs were fitted with a new piston & backing plate to the LHS.

When the transaxle was refitted to the machine & the owner drove it – he suddenly realized just how bad the brakes were before in comparison to how well the machine skids to a halt now!!

Preventative Maintenance Tip

Moral of this story is – if your brakes are not performing too well & making noises that you don’t think are normal – then get in contact with someone who does know & get a professional assessment of things BEFORE they can cost you BIG dollars in repairs & maybe injure someone along the way!